The recent poor weather reminds us of the pressure roads face in times of extremely heavy rain and flash flooding. Not only does the excess water cause immediate and ongoing problems but other hidden dangers can be a major concern.

Traditional manhole covers can eventually succumb to a flood and pop out of their frames leaving them, once the water recedes, lodged in positions dangerous to vehicular traffic and in extreme cases leave voids dangerous for pedestrians too.

That’s why there has been significant interest in our innovative ‘pressure release mechanism’ covers which eradicate the problem overnight.

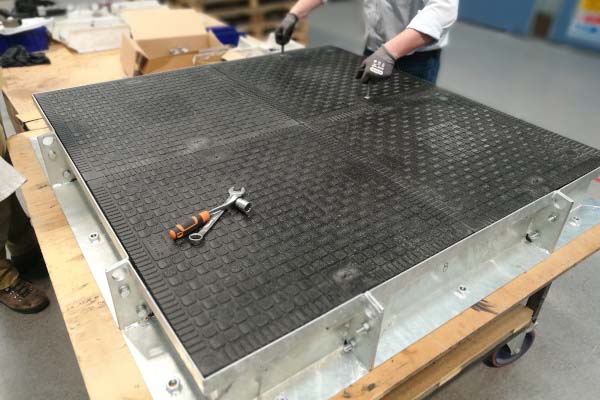

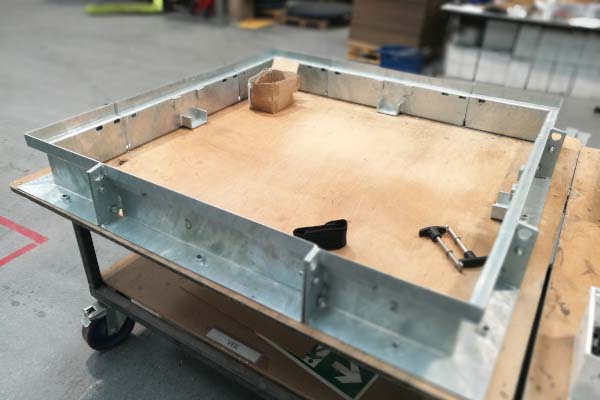

The SSC design ensures the hole/chamber remains covered at all times. When the flood water pressure increases, the cover automatically ‘pops up’ by a maximum of 30 mm but remains in position over the chamber. When the flood subsides it simply drops back into the frame, eliminating the risk of a vehicle running into a raised manhole.

It’s a square D400 product with a 600x600mm clear opening and can be used where there is high speed traffic, specifically for Group 4 applications as defined in the EN124:1994 standards.

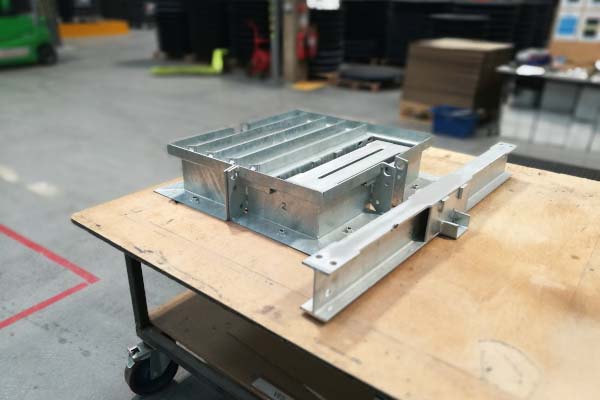

The twin locking mechanism is attached to the frame allowing the cover to move up and down freely in its spring-loaded riser. The cover can only be removed by unlocking the two locks, maintaining its security and integrity.

The DS6 with pressure release system is a real game changer, especially in areas where flash flooding is a continual problem. For further information on this innovative new design, please talk our knowledgeable sales team today.

Contact us or call 01229 814340..