Within many manufacturing plants and food production plants in particular, factory managers are looking at ways of colour coding access covers.

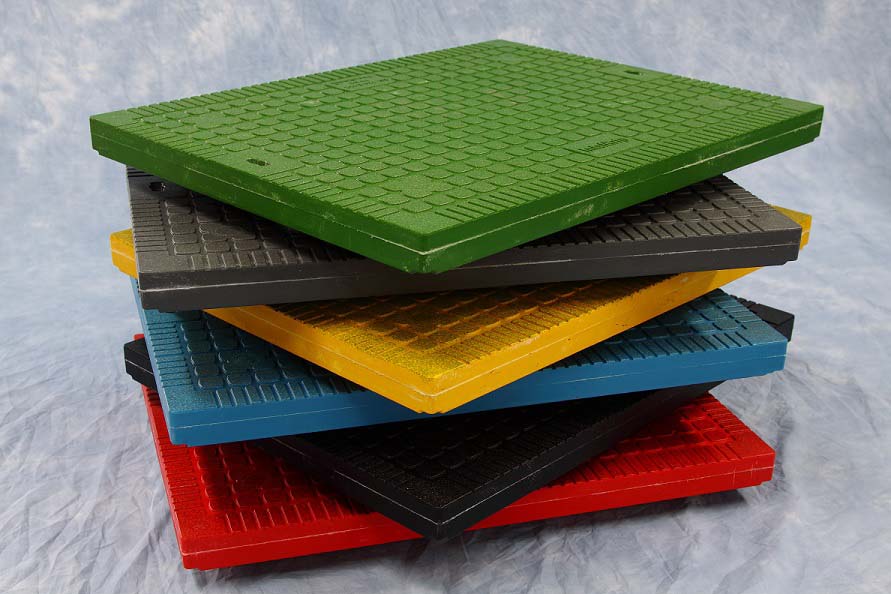

Using different coloured composite manhole covers, rather than the traditional metal, not only provide a lightweight, easy to open solution, but obviously helps factory personnel as they carry out inspections.

All our coloured composite covers also have the facility for watertight seals, that stops inappropriate liquids and detergents from entering sensitive chambers beneath.

In areas prone to liquid on floors and with requirement for regular washing, composite covers also offer a much higher level of safety with their non-slip surfaces prevent likely slips.

We have a range of colours and sizes available and can provide detailed help and advice on any aspect of their application, either as replacements or for new installations.

For further information on coloured manhole covers, please do not hesitate to contact us today.