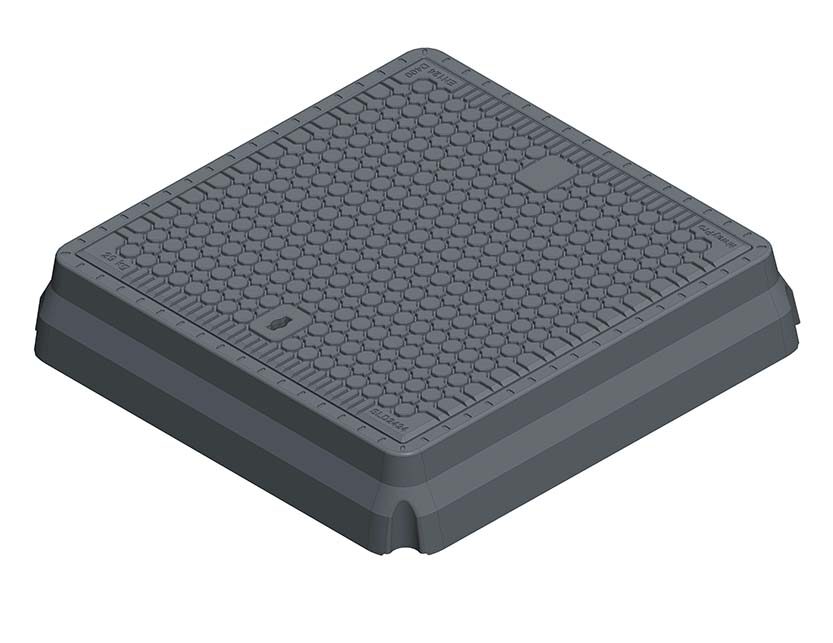

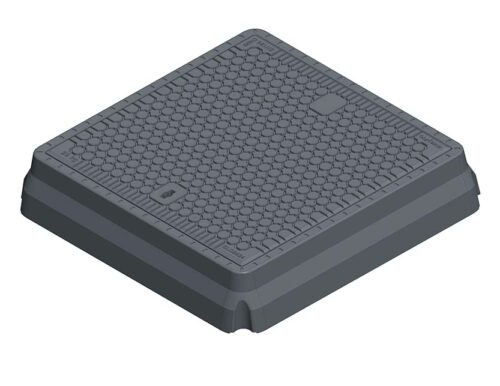

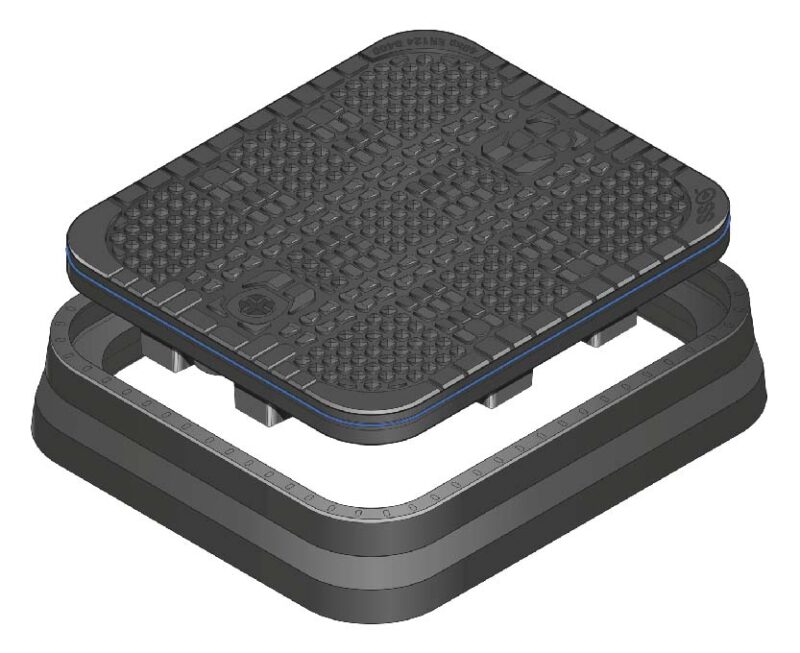

DS6 with pressure release locking mechanism

Manhole covers for highways

The DS6 with pressure release locking mechanism is a square D400 product with a 600x600mm clear opening and can be used and can be used in D400 locations according to EN124-2015 standards.

It is one of the most commonly used sizes for highways. It has a uni-directional tread pattern to improve its anti-skid properties.

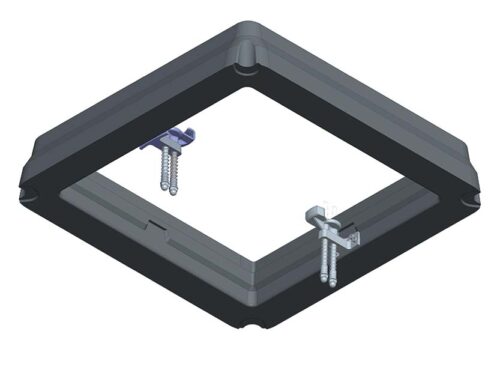

A real game changer in cover locking technology

Allows water to escape but stays safely in position during a flood surge. Puts an end to the dangers caused by covers that stick up or explode out of the ground and means no holes for pedestrians or motorists to fall into during times of flood.

The problem

During heavy rains and subsequent flood conditions, water surges cause traditional manhole covers to be blown out of the ground. Many simply float away with the flood waters or often become stuck in an upright position. It’s easy to see how this creates a huge risk to public safety, with covers either becoming a hazard or simply leaving a hole in the road. Both outcomes having serious consequences for pedestrian and road users.

The solution

Now there is an alternative to traditional covers. The ThruBeam DS6 cover with pressure release locking mechanism allows water to dissipate safely but unlike other designs, the locked cover moves up and down freely in its frame – ensuring public safety with no holes, no hazards, and no flying covers.

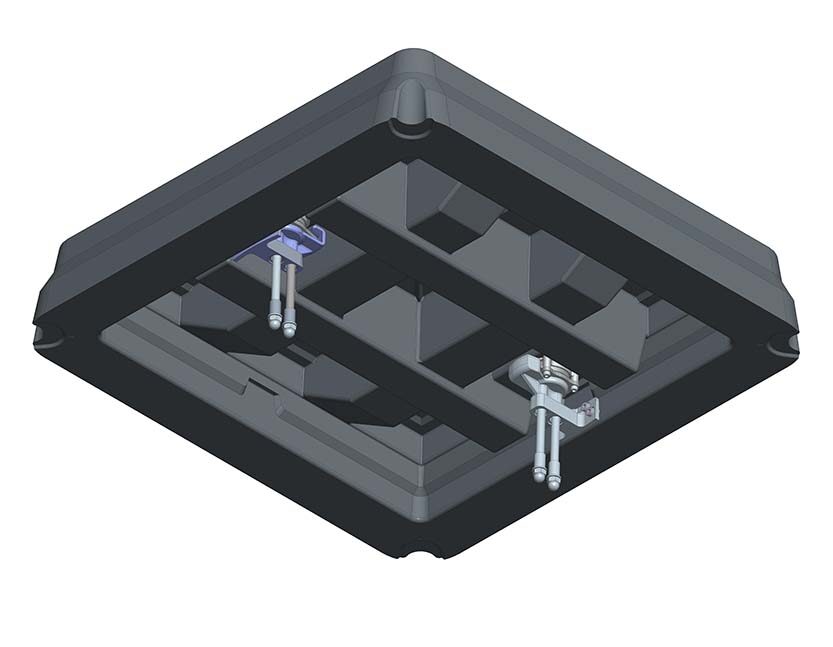

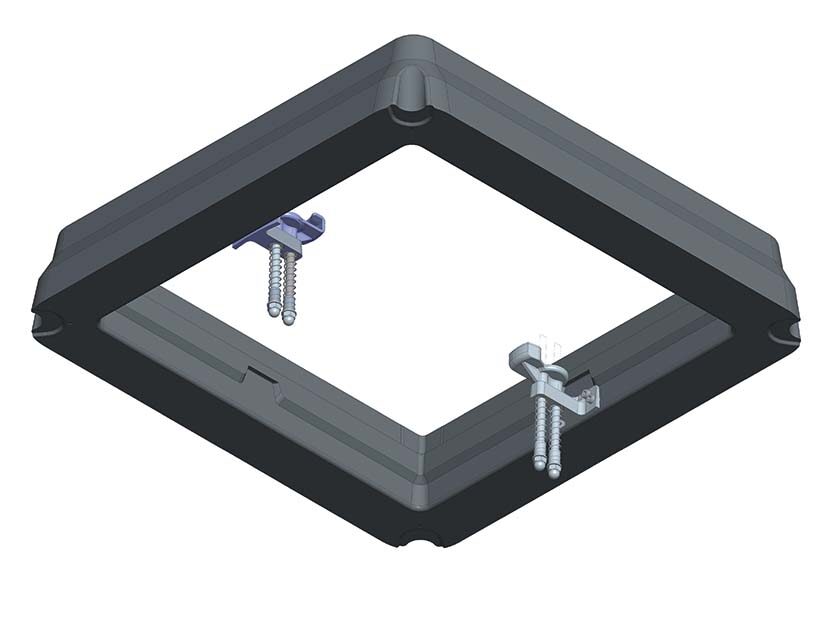

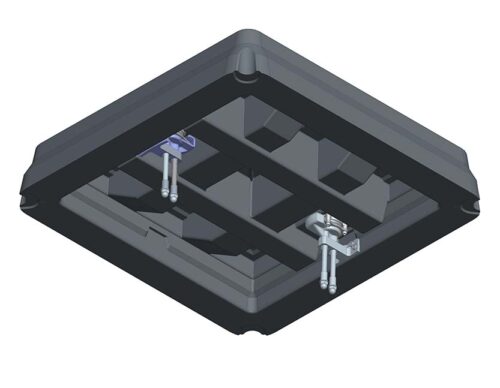

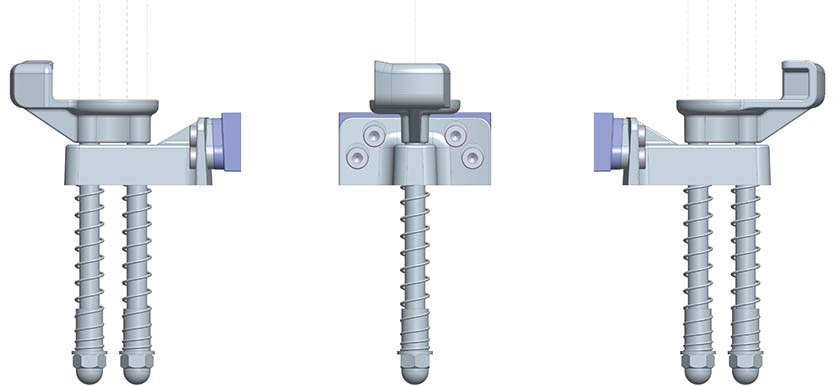

The technology

Building on the technology of the standard DS6 cover, the new DS6 cover with pressure release locking system features a twin restraining mechanism which allows the cover to move up and down in its spring-loaded frame while remaining locked at all times. When the water pressure reaches 0.5 bar, the cover rises by a maximum of 30mm dissipating the water and pressure.

How it works

When a water surge occurs, the cover lifts just enough to let the water escape and then floats back down into position when the water starts to recede. If someone then walks or drives over the cover, it simply drops back into its frame. Most importantly, a vehicle can safely drive over a raised cover without damage to either the cover or the tyre.

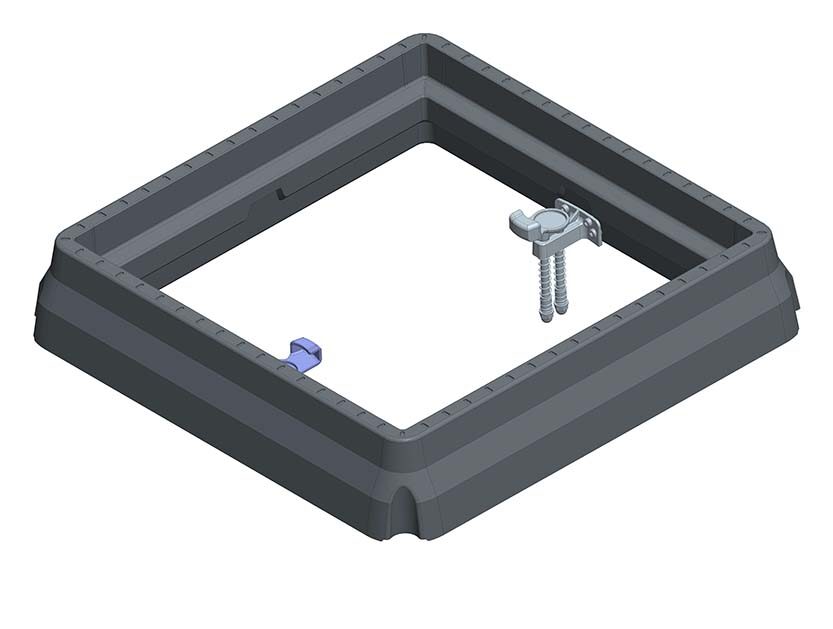

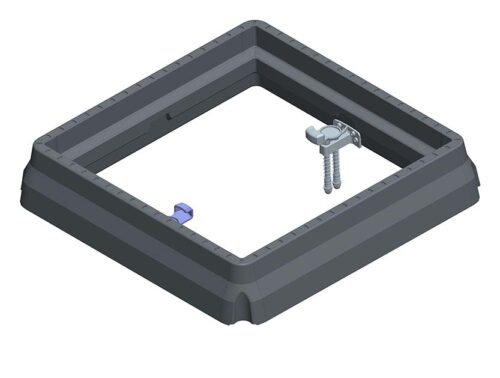

Locking mechanism

The twin locking mechanism is attached to the frame allowing the cover to move up and down freely in its spring-loaded riser. The cover can only be removed by unlocking the two locks, maintaining its security and integrity.

A limit to the rise

When a water surge arrives and the water pressure beneath the cover builds, the cover pops up by a maximum of 30mm. This dissipates the water and pressure while ensuring that the cover doesn’t become a hazard for pedestrians or motorists.

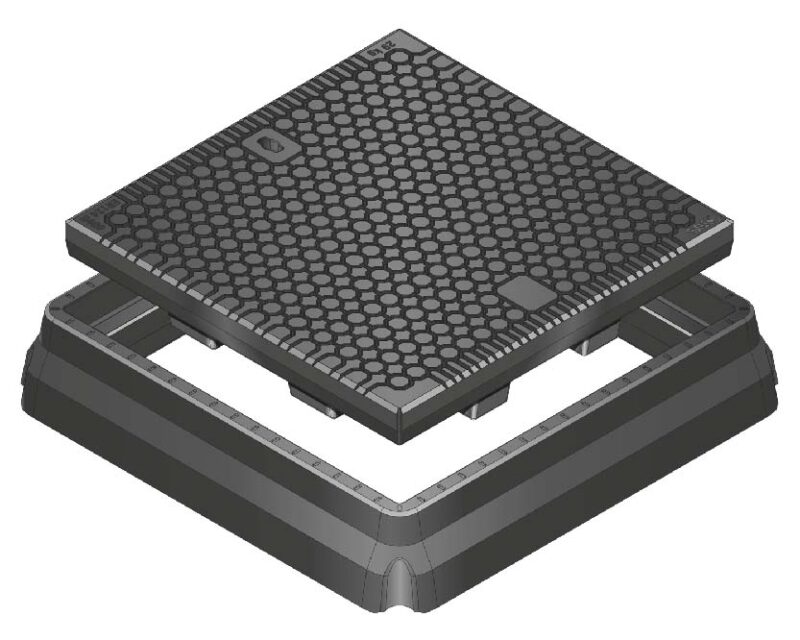

Description

Cover Specifications

| Load Rating | EN124:2015 Class D400 |

| Clear Opening | 610 mm x 610 mm |

| External dimensions | 672 mm x 672 mm |

| Skid resistance (wet polishes) | PSRV 60 |

| Weight | 29 Kg (63.8 lbs) |

| Lifting points | Single key housing |

| Tread depth | Tread depth complies with EN124:2015 Class D400 |

| Tread type | Embedded aggregate |

| Wear indicators | Two moulded |

| Markings | Week, year and location of manufacture moulded into underside of cover. Cover size, weight on the top surface. |

| Corrosion / chemical resistance | All component parts are resistant to chemical attack, diesel, petrol, salt and water or a combination of the above over the lifespan of the cover. Surface discolouration is acceptable in service |

| Combustion properties | All component parts do not support combustion. Products of combustion do not contain harmful chemicals (eg bromides) |

| Sealed | No |

| Vented | No |

| Carbon footprint | Low |

| Material | Advanced fibre glass composite |

| Client logo | Can be provided on top surface |

| Security features | Available on request |

Designs and specifications are subject to alteration, so that continuous improvement can be undertaken

Frame specification

| Load Rating | EN124:2015 Class D400 |

| Clear Opening | 610 mm x 610 mm |

| Weight | 15 Kg (33 lbs) |

| External dimensions | 810 mm x 810 mm – 150 mm deep |

| Material | Advanced fibre glass composite |

| Security | Designed to accept optional bolting system |

| Installation | See installation page |